Capabilities

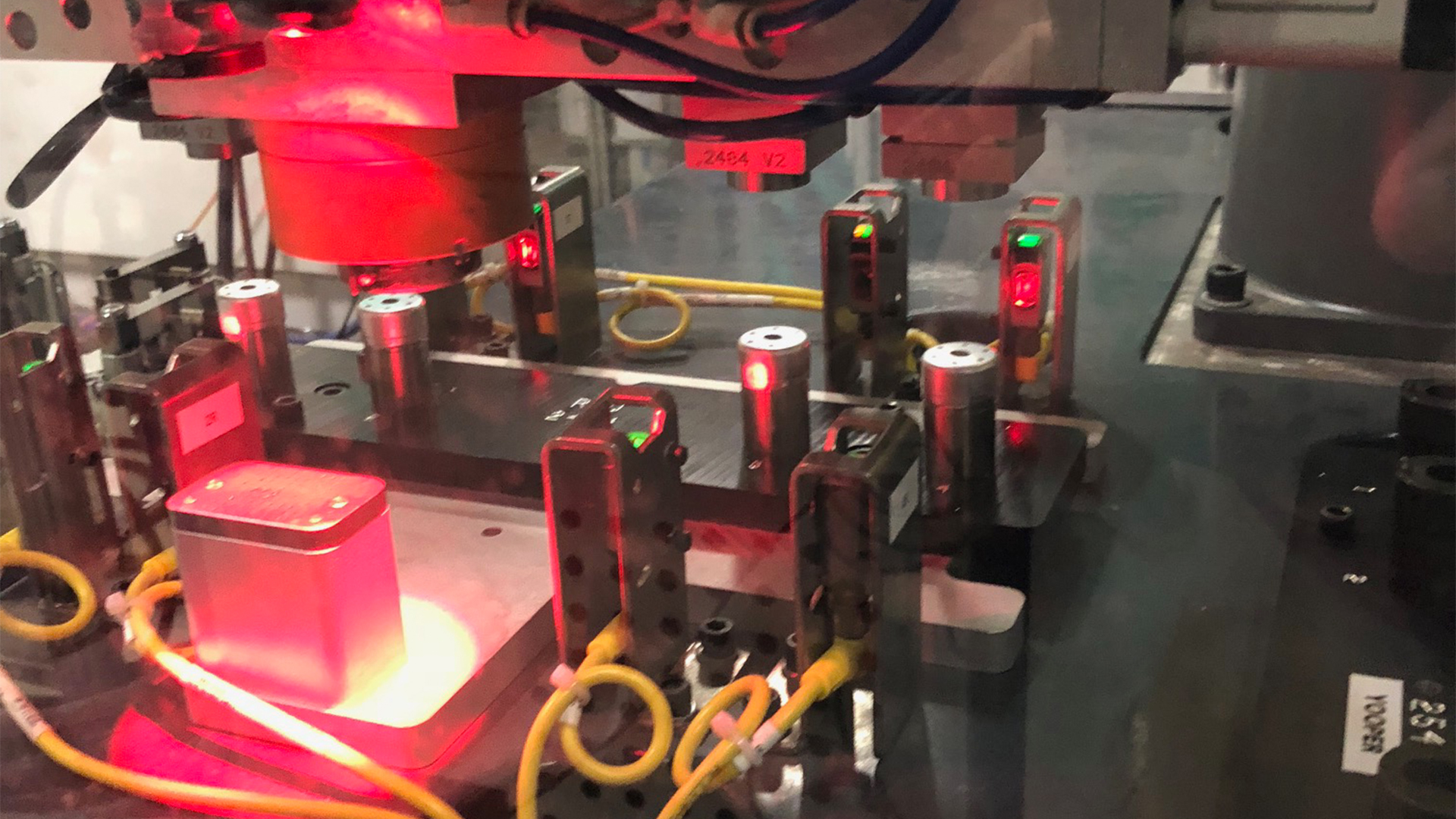

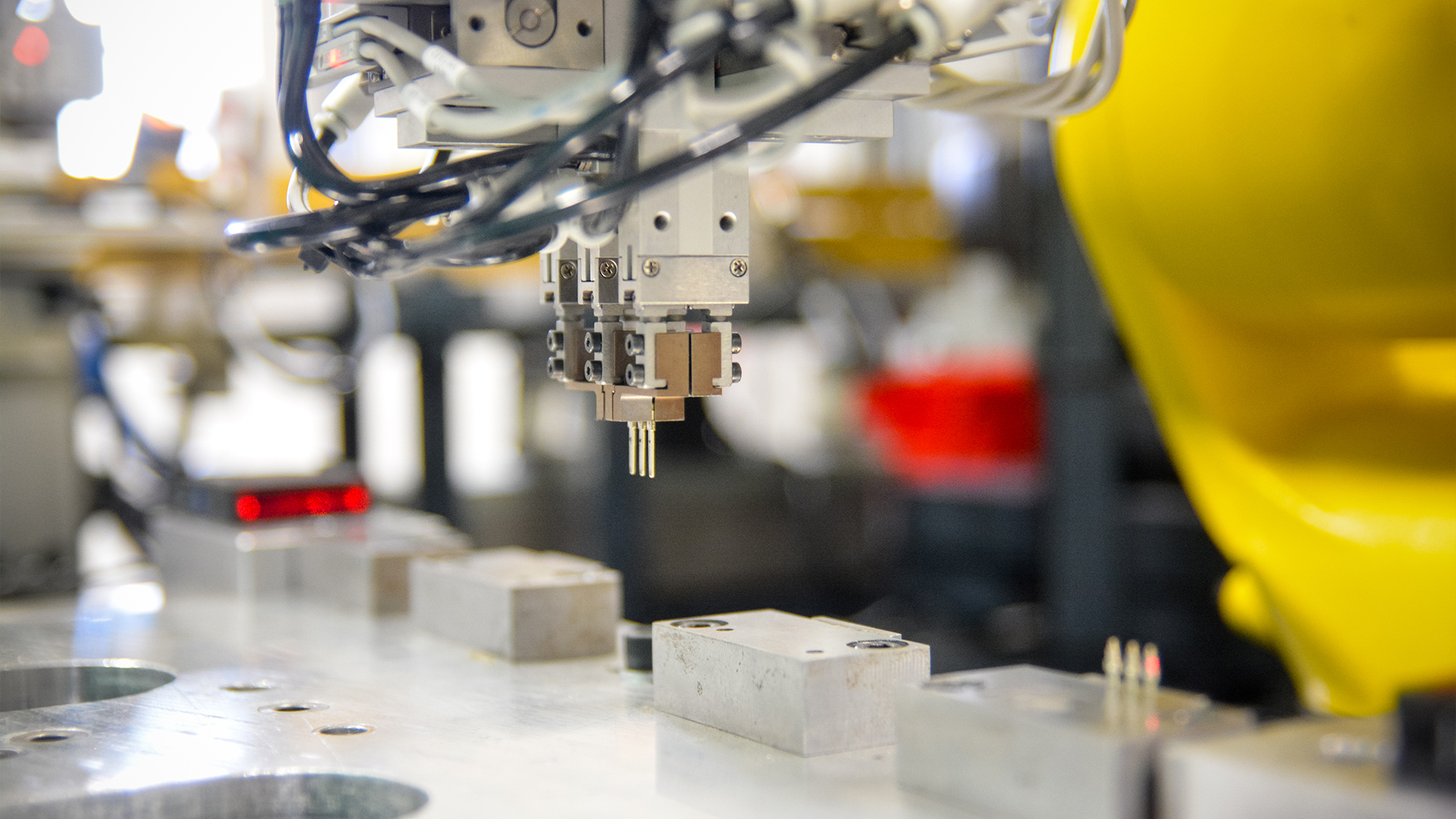

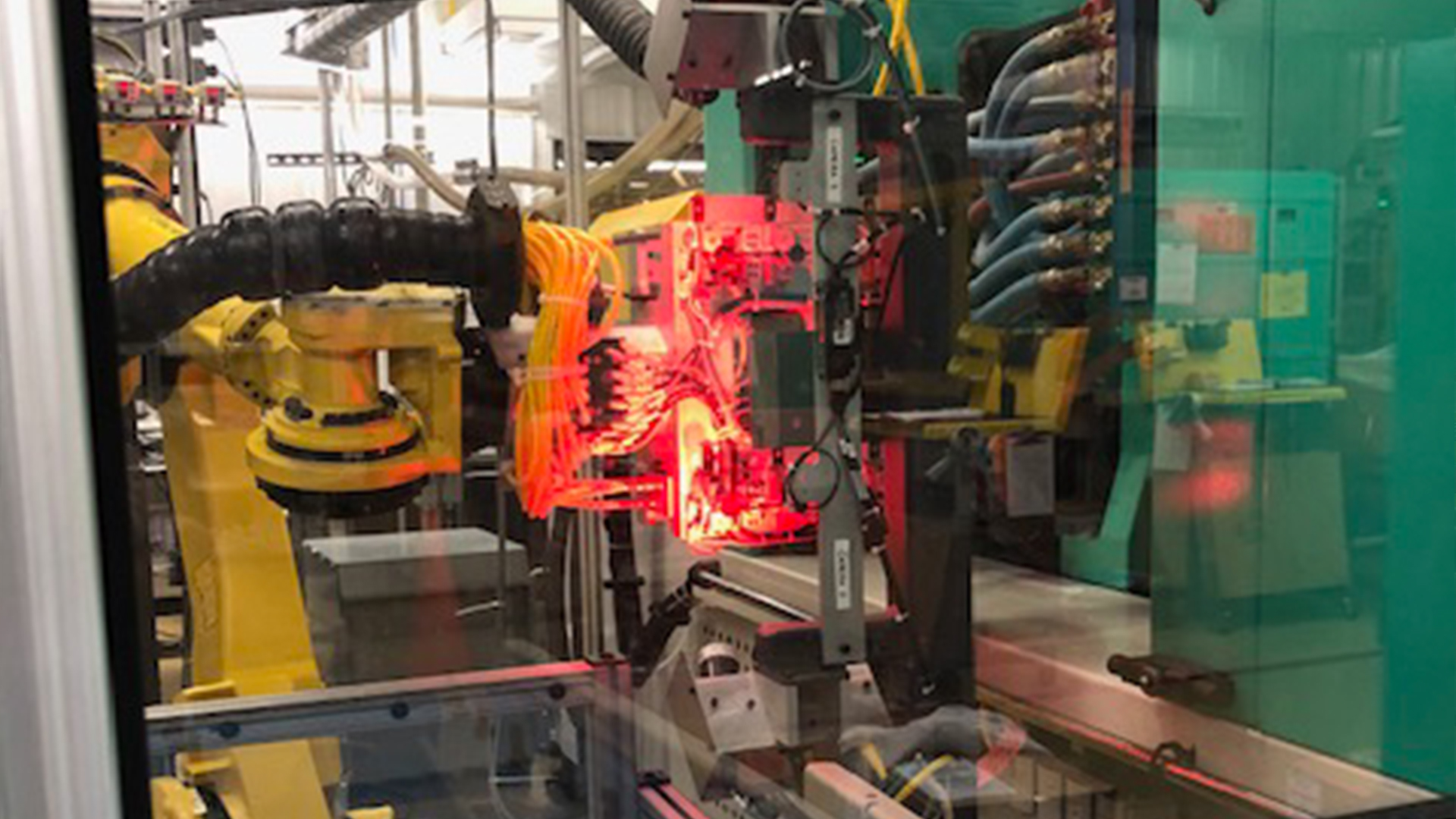

Our state-of-the-art facilities deliver the highest quality custom injection molded products to meet each customer’s unique specifications. By offering a variety of different mold types, we tailor a manufacturing approach to ensure no matter what kind of molding is needed, we have the right solution. Our investment in new technologies and the knowledge and skill development of our staff prepares us to handle any process, from simple to highly complex.

Engineering Solutions

By using a data-driven scientific approach to developing and optimizing the injection molding process, we can provide more consistent processing and parts quality for our clients. This ensures that they will receive the exact product they ordered and in a timely manner.

Secondary Services

Understanding that our customers want all aspects of the mold making process done at once, we provide additional services like pad printing, sonic welding and tape and reel packaging, just to name a few. These value-added services provide our customers with a one-stop shop experience and ease of mind that we’ve taken care of all the details, big and small.

The Ironwood Difference

From our beginnings in 1979, our vision has always been the same, “To be a world class injection molder of complex projects.” Today, we still remain true to our vision and use the latest technologies to manufacture the highest quality molds. This, in turn, leads to exceptional customer satisfaction.